SURREY MEMORIAL HOSPITAL

ImageTech Lab

Sound Camel had the privilege of visiting Simon Fraser University’s leading medical imaging research facility to identify methods of attenuating noise propagating from the MRI scanning room to adjacent office spaces.

Date: September 30, 2024

Location: Surrey Memorial Hospital, Building A, Level 1, 13750 – 96 Avenue, Surrey, BC, V3V 1Z2

Sources of Noise

This section outlines the primary sources of noise in the MRI facility and its impact on the control room environment.

The MRI machine is the primary source of noise in the lab, emitting up to 73dB in the adjacent control room when performing the angiogram sequence and 42dB at rest. This 31dB difference is perceived as approximately eight times louder than baseline to the human ear.

The rapid switching of electromagnetic gradients and Lorentz Forces that cause the coils to vibrate create mechanical vibrations that transfer to the surrounding structures, including the MRI machine’s housing, leading to the emission of sound waves. This creates the knocking, banging and buzzing noises experienced by staff and patients.

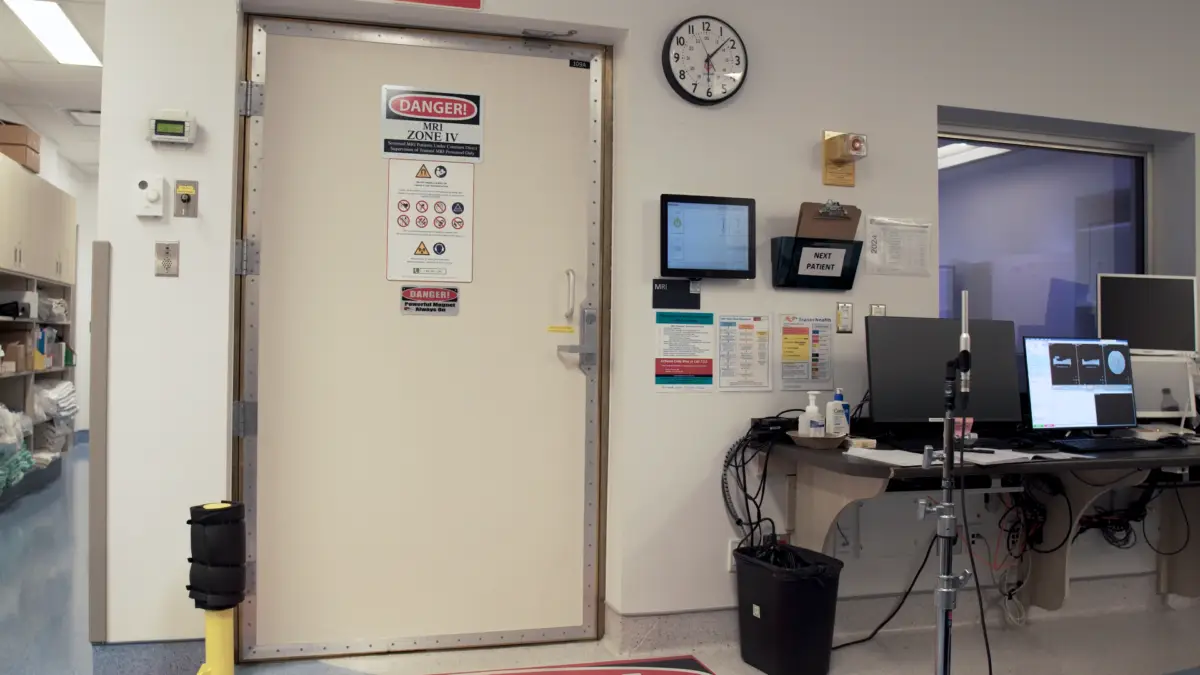

Sound from the MRI machine reaches the control room through flanking paths like the scanning room door, conduits, waveguides and HVAC system in three categories:

Airborne Sound Leakage: Even when the door is closed, small gaps around the edges of the door create an imperfect seal which allows noise to escape, contributing to the sound reaching the control room.

Structure-Borne Transmission: Structure-borne noise travels through rigid materials like metal conduits, piping and wall framing, which act as pathways for vibration transmission. Conduits and waveguides transmit noise from the MRI room to the control room.

Duct-Borne Noise:The HVAC system transmits sound through the ducts, carrying noise from the MRI room into other areas like the lab offices and MEG room.

Our observations suggest that the primary sources of noise in the control room and adjacent offices are airborne and duct-borne. The following recommendations outline potential solutions to address these issues, along with rough cost estimates.

HVAC Air Diffusers

MRI Scanner Room Door

MRI RF Waveguides

Solutions:

1. Reroute HVAC

To reduce noise in the control room and adjacent hallway caused by the HVAC system shared with the MRI room, the best solution is to either relocate the ducts or install acoustical duct silencers or dampers. Below is an outline of both processes.

- Plan a new duct path for the MRI room, routing them away from the control room and hallway. Ideally, ducts should have dedicated pathways and not serve multiple rooms.

- If feasible, create separate HVAC zones for the MRI scanning room and the control room/hallway to contain noise and vibration from the MRI equipment within the scanning room.

- Install the new ductwork and seal all joints and seams using acoustic sealant to prevent sound leakage. Add vibration isolation hangers to further reduce noise.

OSI Green Series Acoustical Caulk: This sealant is designed to reduce sound transmission through gaps and cracks in walls and around conduits. It remains flexible and can be painted over once dry, making it ideal for sealing conduit penetrations in walls.

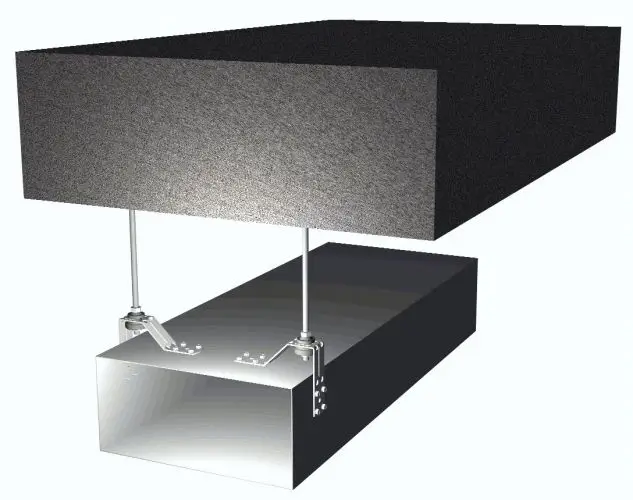

Argo Air Duct Vibration Isolation V Bracket 3/8″ Threaded Rod for Square & Spiral: This vibration isolation bracket fits both square and spiral air ducts.

Cost:

HVAC contractor quote required.

Relocate Ducts

Air Duct Vibration Isolation

2. Insert Acoustical Duct Silencers or Dampers

Acoustical duct silencers are designed to reduce noise traveling through ducts (up to 30dB), improving the acoustic environment in the adjacent areas. If total duct isolation between spaces isn’t feasible, silencers should be installed in the ducts connecting the MRI room to the hallway and control room to absorb noise while maintaining airflow.

Instructions:

Assessment of Duct Noise Pathways:

- Identify the ducts where noise from the MRI room is escaping into adjacent spaces, particularly toward the hallway and control room.

- Determine duct sizes and existing noise levels. This will help in selecting the right silencer to achieve the desired noise reduction.

- Evaluate the airflow requirements to ensure the silencers will maintain sufficient airflow while reducing noise.

Selection of the Acoustical Silencer:

- Choose a silencer based on the duct size and configuration (rectangular or round ducts) and the targeted noise reduction level. Ruskin offers various models, such as narrow, medium, and wide silencers, each with different insertion loss characteristics. Narrow silencers might be suitable where space is limited, while wide silencers provide greater noise reduction. For the MRI facility, consider a silencer model with high sound attenuation across a wide frequency range, including low frequencies.

Installation Guidelines:

- Locate the ducts to be treated, ideally close to the MRI room to maximize noise reduction before it propagates further.

- Cut a section of the duct to insert the silencer, ensuring the length of the silencer follows the manufacturer’s installation recommendations for positioning.

- Secure the silencer using appropriate methods such as clamps, screws, or welding, ensuring the connections are airtight to prevent any air leakage.

- Seal joints and edges using acoustic sealant or gaskets to maintain airtightness and improve acoustic performance.

- Perform a functional test to check both noise reduction and airflow after installation.

Cost:

HVAC contractor quote required.

Rectangular Reactive Silencers

3. Acoustic Ceiling Insulation

Install 3″ Rockwool Safe ‘n’ Sound on T-bar ceiling around the perimeter of the MR scanner room and fully in the adjacent hallway and control room to absorb broadband frequencies and attenuate noise.

Instructions:

- Ensure Compatibility: Verify that the T-bar grid can support the weight of the Rockwool Safe ‘n’ Sound at 2.4 lb/ft³ (0.6 lb/ft²).

- Check whether pot lights and recessed fluorescent troffer lights are IC-rated (insulation contact) or leave adequate space around them for heat dissipation.

Costs:

- $96.34 per 60 ft² (5.58 m²) of stone wool batt (approximately 8 packages or $770.72 total)

- $22 per installed batt (estimated 64 batts or $1408 total)

Installing 3" Rockwool Safe 'n' Sound

Placing stone wool batts above ceiling tiles can significantly enhance acoustic performance by absorbing sound waves that would otherwise reflect off hard surfaces, including the copper Faraday cage. This additional layer of insulation reduces the amount of sound traveling through the ceiling, effectively minimizing echoes and improving overall sound clarity in the space. Stone wool’s dense structure captures and dissipates sound energy, making it especially effective for controlling both airborne noise and reverberation. This installation approach is particularly beneficial in environments with existing drop ceilings with acoustic tiles to maintain a more comfortable, focused atmosphere.

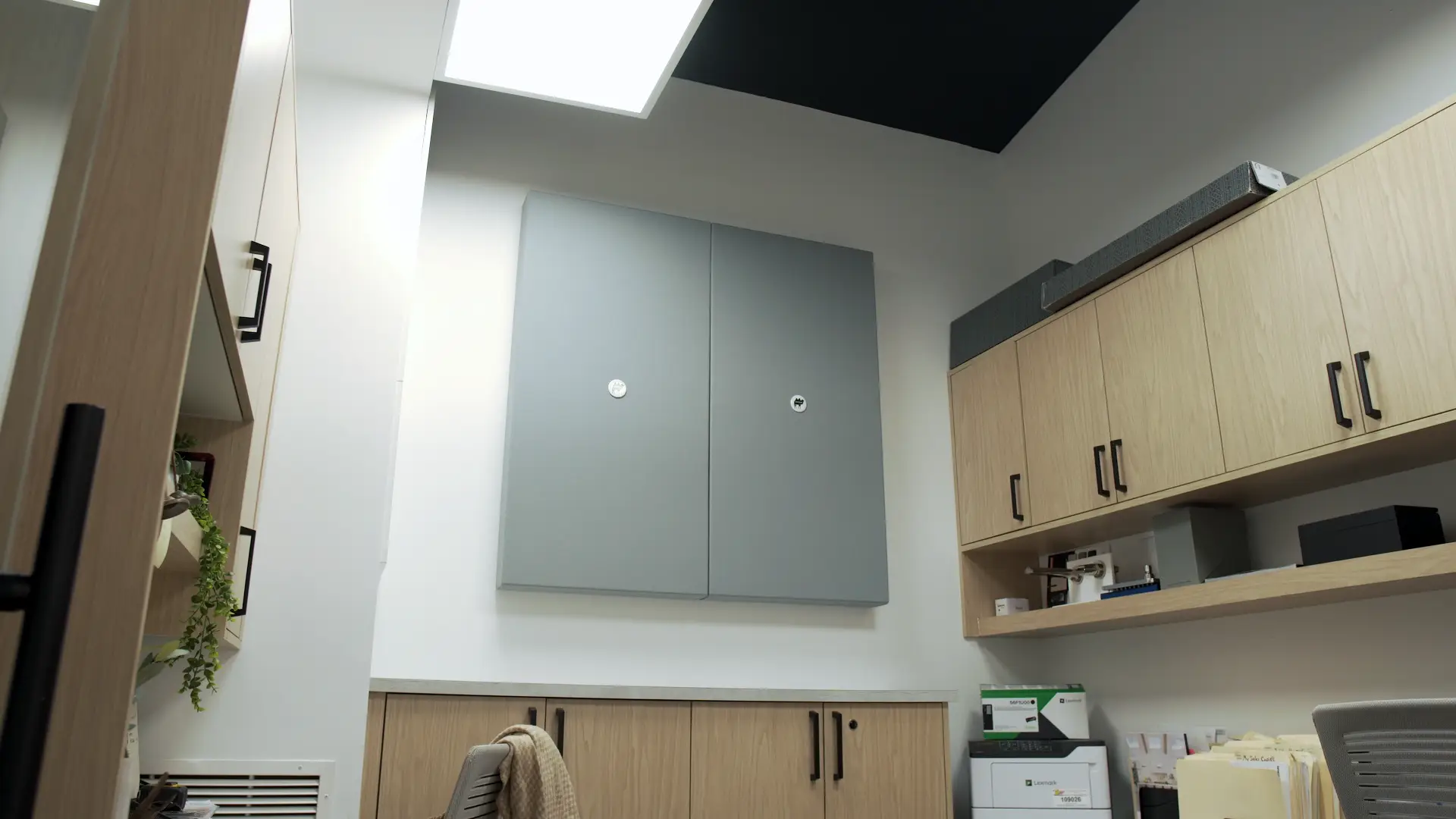

Perimeter of the MRI Scanning Room

4. Acoustic Door

Install 76.5″ x 100.5″ X 6″ acoustic barn door in MRI scanning room to block sound from penetrating existing thin copper-lined door.

Instructions:

- Install barn door hardware on the inside of the MRI scanning room by existing door opening.

- Mount the acoustic barn door panel on the heavy duty tracks.

Recommended Products:

Sound Camel Acoustic Door Panel: Custom acoustic barn door to provide full coverage over the entire door frame to block noise from all angles.

Magic 2 Legno Sliding Door System: Wall-mount sliding system for doors weighing up to 176 lbs (80 kg). Model 1800.

6 Inch Recessed Finger Pulls: Four durable 304 stainless steel finger pulls for dual-sided access.

Costs:

- $1350 acoustic barn door with pull handles

- $741 heavy duty concealed door hardware

- $125 installation

Acoustic Door Panel

Acoustic Barn Door Open Position

5. Broadband Acoustic Panels

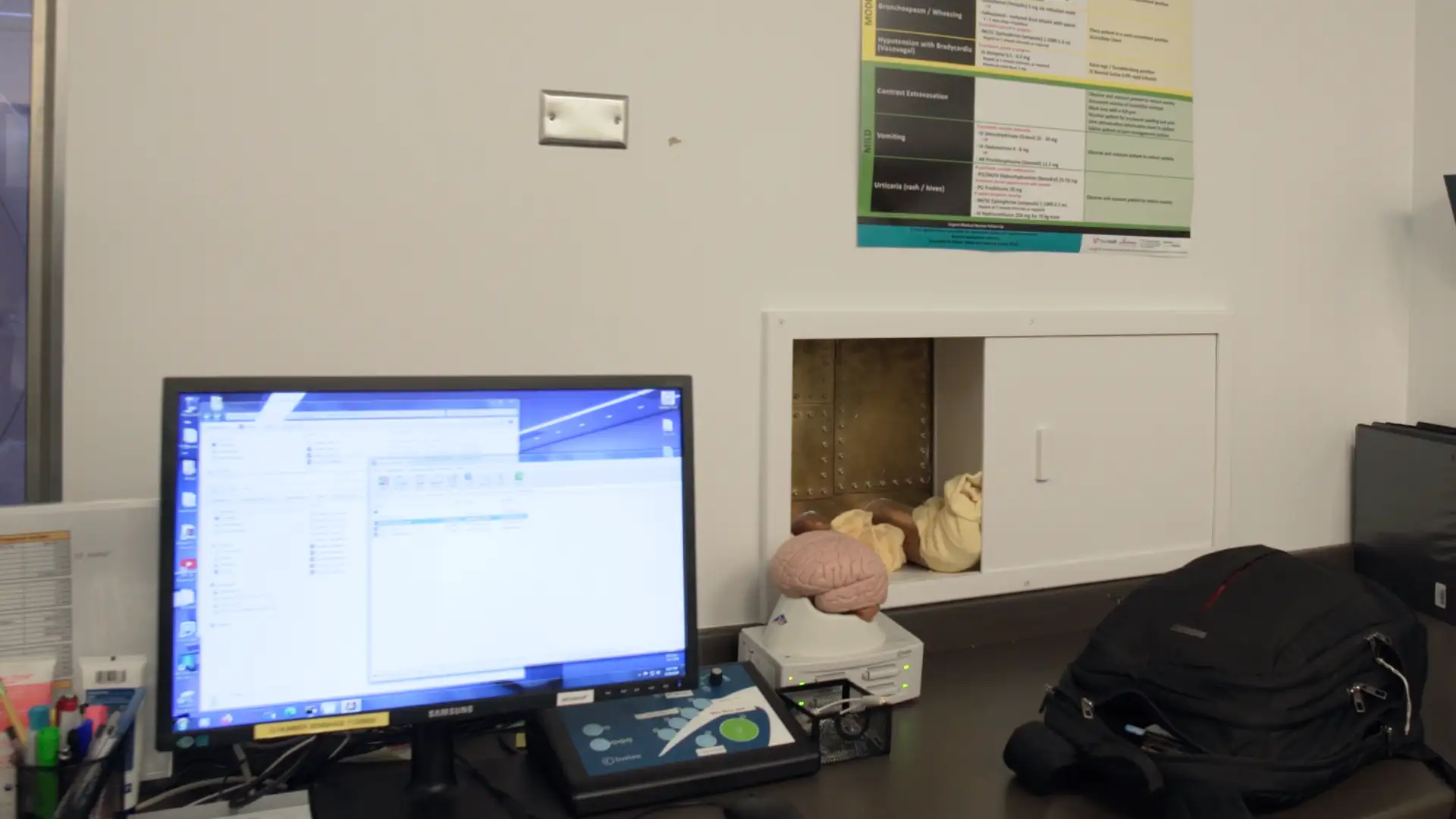

Install 4″ broadband acoustic panels centered on the back wall of the MRI scanning room, aligned with the bore of the machine. This installation aims to minimize reflections towards the control room, enhancing acoustic performance and reducing noise interference in the nearby MEG room and offices. Additionally install 1 horizontal acoustic panel over the RF waveguides access door in the control room (easily removable).

Instructions:

- Install 8 Camel Cleats on the back wall centered with the bore of the MRI machine and 2 cleats over the RF waveguides access panel in the control room.

- Vertically mount 8 48″ x 24″ x 4″ acoustic panels on the french cleats without gaps between the panels in the scanning room and one horizontal acoustic panel over the waveguides access panel in the control room.

Recommend Products:

Sound Camel Acoustic Panels: Wall or ceiling mountable in any orientation with included cleat-lock mounting system.

Costs:

- $162 x 9 acoustic panels ($1458 total)

- $50 x 9 acoustic panel installation ($450 total)

- $295 delivery

MRI Scanning Room Wall Acoustic Panels